How a Rush Hat Is Made — Sunnyrush Fire Hydrant Stamp Rally

How does rush become a hat?

From the fields, rush is dried, sorted, woven, and shaped into the hat you wear. Follow Sunnyrush’s fire hydrant exhibition route to learn about the journey of rush and hear stories from Yuanli. Each stop holds memories of the land, time, and skilled hands.

How to Join:

Step 1: Get a Stamp Card at the “Songshan Cultural and Creative Park Service Center” or at the “Sunnyrush Pop-up Store at Songshan”.

Step 2: Visit each fire hydrant on the map and collect stamps!

Step 3: Collect 10 stamps to receive a gift or a discount voucher at the Sunnyrush Pop-up Store.

-

The tour starts at Fire Hydrant No. 1.

-

Stamp cards and gift redemption are available at the Sunnyrush Pop-up Store (Open daily 11:00–19:00).

Event Period: June 25 – August 3

-

1,000 gifts available while supplies last.

-

Discount vouchers are unlimited.

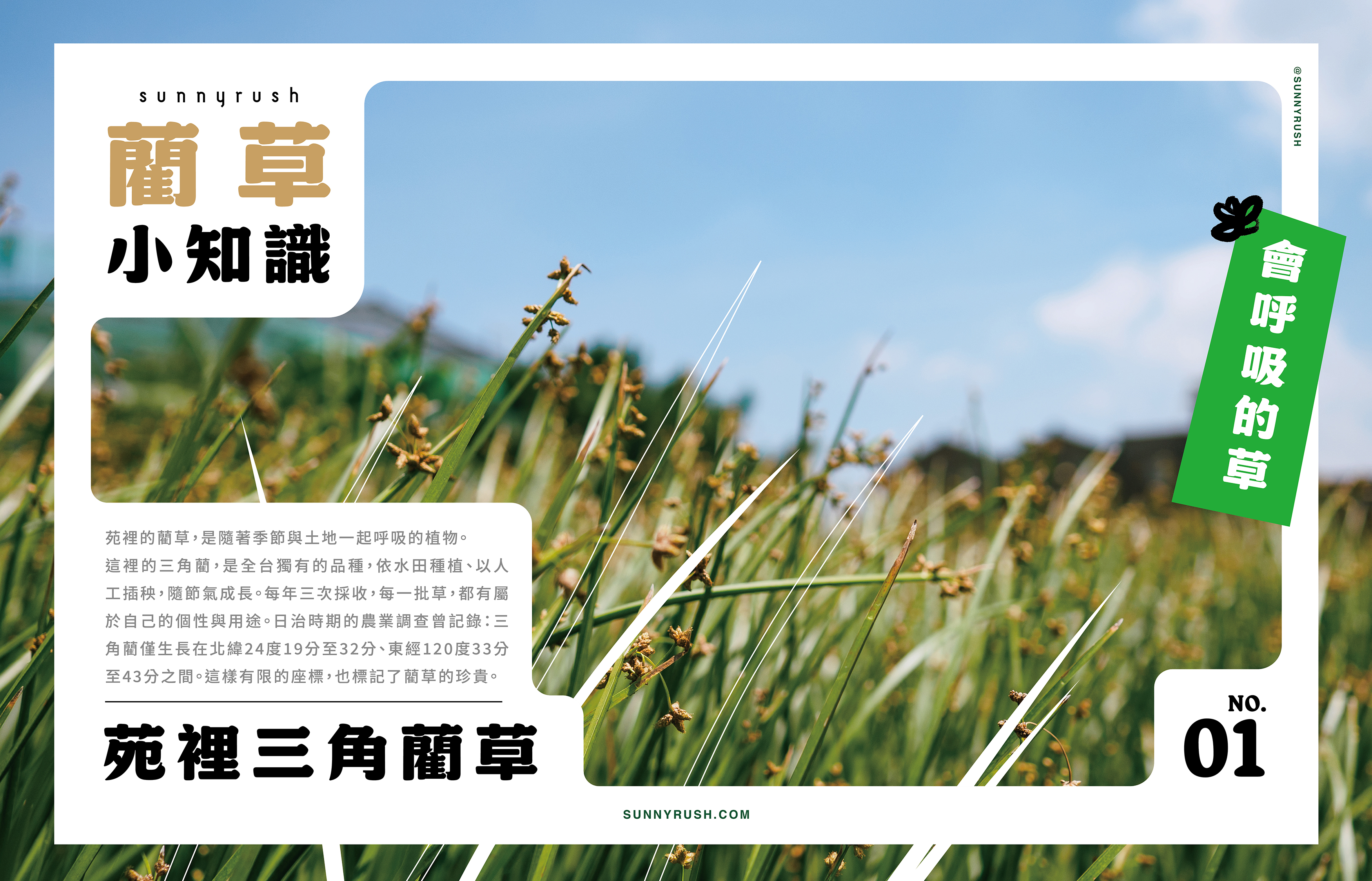

Rush Fact 01: Yuanli Triangle Rush

The Grass That Breathes

The rush of Yuanli breathes in harmony with the seasons and the land.

The “Triangle Rush” is a unique species native to Taiwan. It is cultivated in paddy fields and transplanted by hand, growing in sync with nature’s rhythms. Harvested three times a year, each batch carries its own distinctive character and purpose.

During Japanese rule, agricultural surveys documented that Triangle Rush grows only within the narrow coordinates of 24°19′ to 24°32′ North Latitude and 120°33′ to 120°43′ East Longitude. This limited habitat highlights the rarity and precious value of this plant.

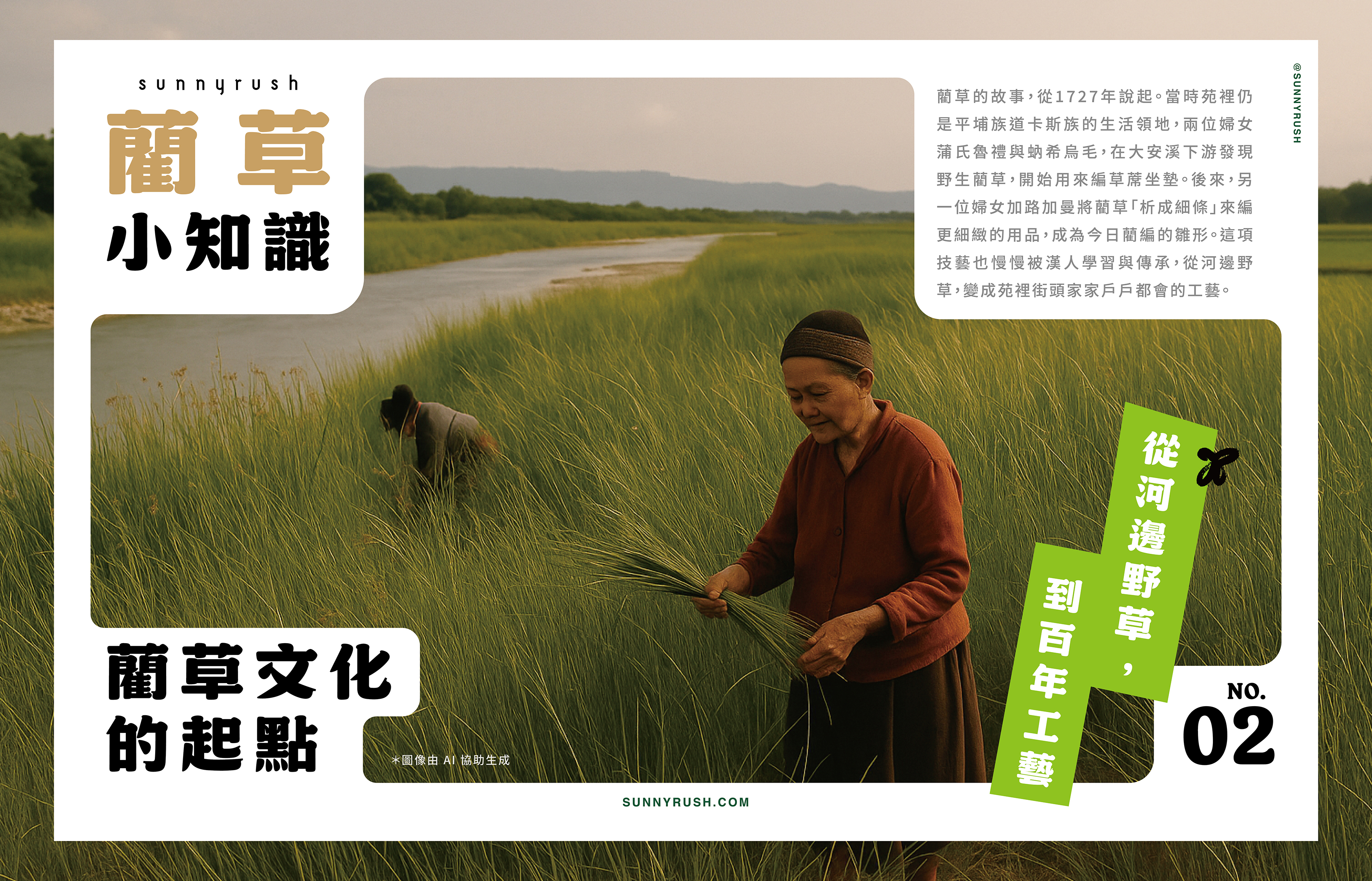

Rush Fact 02: The Origin of Rush Craft

From Riverbank Grass to a Century-old Craft

The story of rush began in 1727. In those days, Yuanli was home to the Taokas people. Two women, Pu Lu-Li and Rui Xi-U-Mao, found wild rush growing by the Daan River and started weaving mats and cushions. Later, another woman, Ka-Lu-Ka-Man, developed a way to slice the rush into finer strips, creating more delicate crafts — the beginning of modern rush weaving.

The craft was gradually passed on to Han settlers, turning wild river grass into a beloved household skill in Yuanli.

Rush Fact 03: Ms. Hong Yang

Taiwan’s First Rush Hat Artisan

In 1897, a woman named Hong Yang from Yuanli was commissioned by the Japanese Governor-General’s Office to weave Western-style hats using rush. She not only succeeded but also became the first artisan in Taiwan to turn rush into hats.

Thanks to her groundbreaking work, Hong Yang became one of the most respected women under Japanese rule.

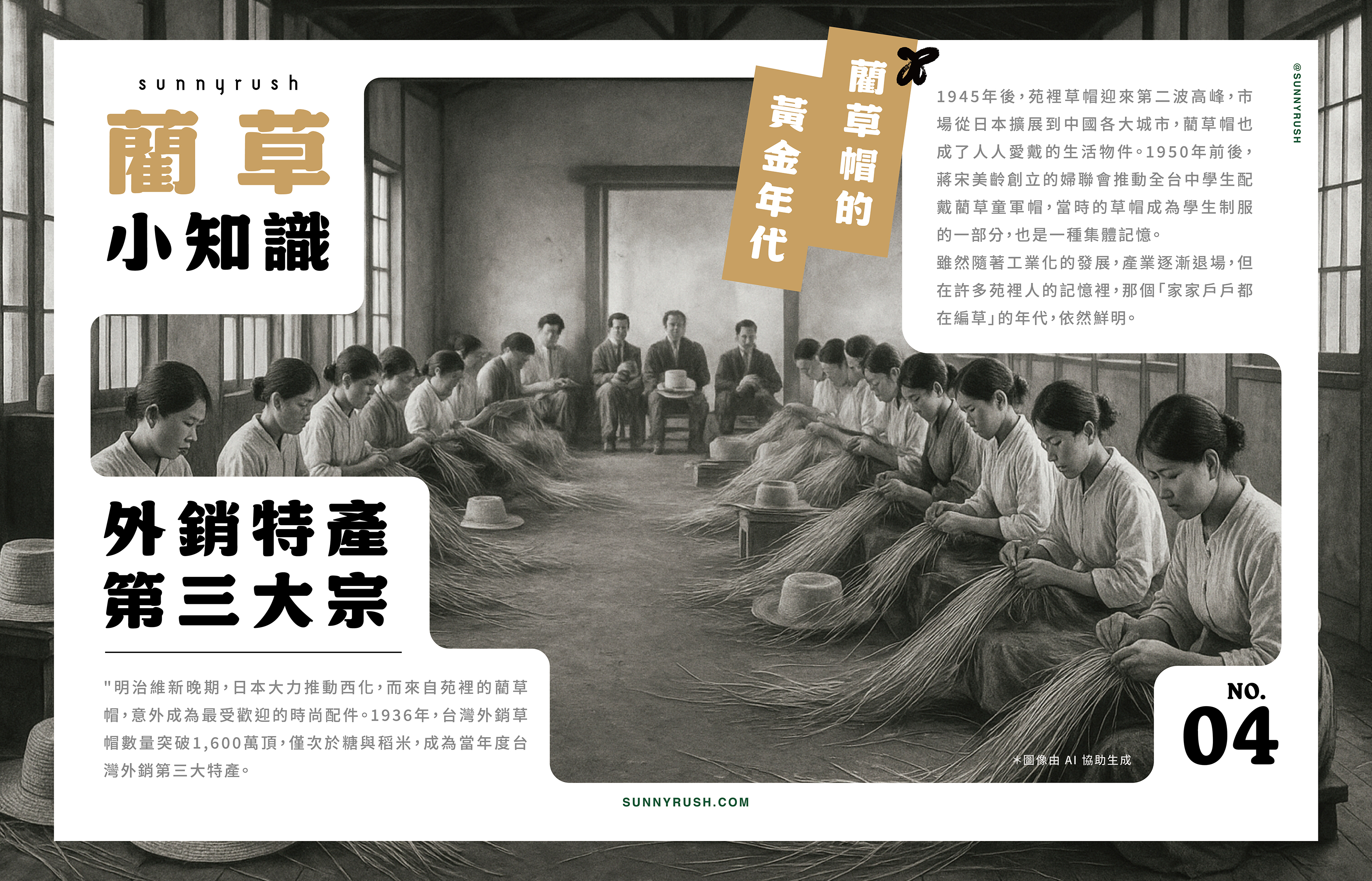

Rush Fact 04: Taiwan’s Third Largest Export

The Golden Age of Rush Hats

In the late Meiji era, as Japan promoted Westernization, rush hats from Yuanli unexpectedly became a fashion trend. By 1936, Taiwan’s export of rush hats exceeded 16 million pieces, ranking third after sugar and rice.

After 1945, Yuanli’s rush hat industry entered a second boom, expanding its market from Japan to major cities in China. Rush hats became a popular everyday accessory. Around 1950, with support from Soong Mei-ling’s Women’s League, rush scout hats became part of student uniforms across Taiwan — creating a shared memory for many.

Although the industry declined with industrialization, for many people of Yuanli, the days when every household wove rush hats remain vivid memories.

Rush Fact 05: The Industry’s Decline

Industrialization Quieted a Traditional Craft

In the past, rush weaving was common in Yuanli homes. Women turned stalks of rush into hats and cushions, providing essential income for their families.

But starting in the 1970s, Taiwan entered a period of rapid industrialization. Plastic products quickly replaced natural materials — cheaper and faster to produce. Many women chose stable, better-paying jobs in garment and electronics factories.

As the world changed, rush weaving gradually faded, becoming a craft remembered mostly in people’s memories.

Rush Fact 06: A New Beginning

Those Who Started Again Gave New Life to an Old Craft

After years of silence, the voice of rush quietly returned in the 1990s. Local teachers and craftsmen in Yuanli began offering rush-weaving classes. Associations, community groups, and farmers’ organizations actively promoted the craft, bringing it back into classrooms and communities.

Skilled women gathered once again — from loving to weave, to mastering the craft, and eventually teaching others. Later, teams like Sunnyrush joined in, blending design with tradition, connecting the old craft with new audiences through exhibitions and fieldwork.

The hands of tradition are no longer alone. One stalk at a time, rush has found its future again.

Rush Fact 07: A New Look for Rush Hats

When Young People Join, the Craft Comes Alive

Today, more and more young people are returning to Yuanli, working with craftsmen to explore new possibilities. Some design hats, bags, and jewelry; others organize exhibitions and join markets — bringing rush out of museums and into daily life.

Sunnyrush is one of these teams, walking alongside the craft — from fields to exhibitions, from teaching to product development — using new language to engage more people.

Tradition isn’t just a memory; it continues to grow and take on new forms.

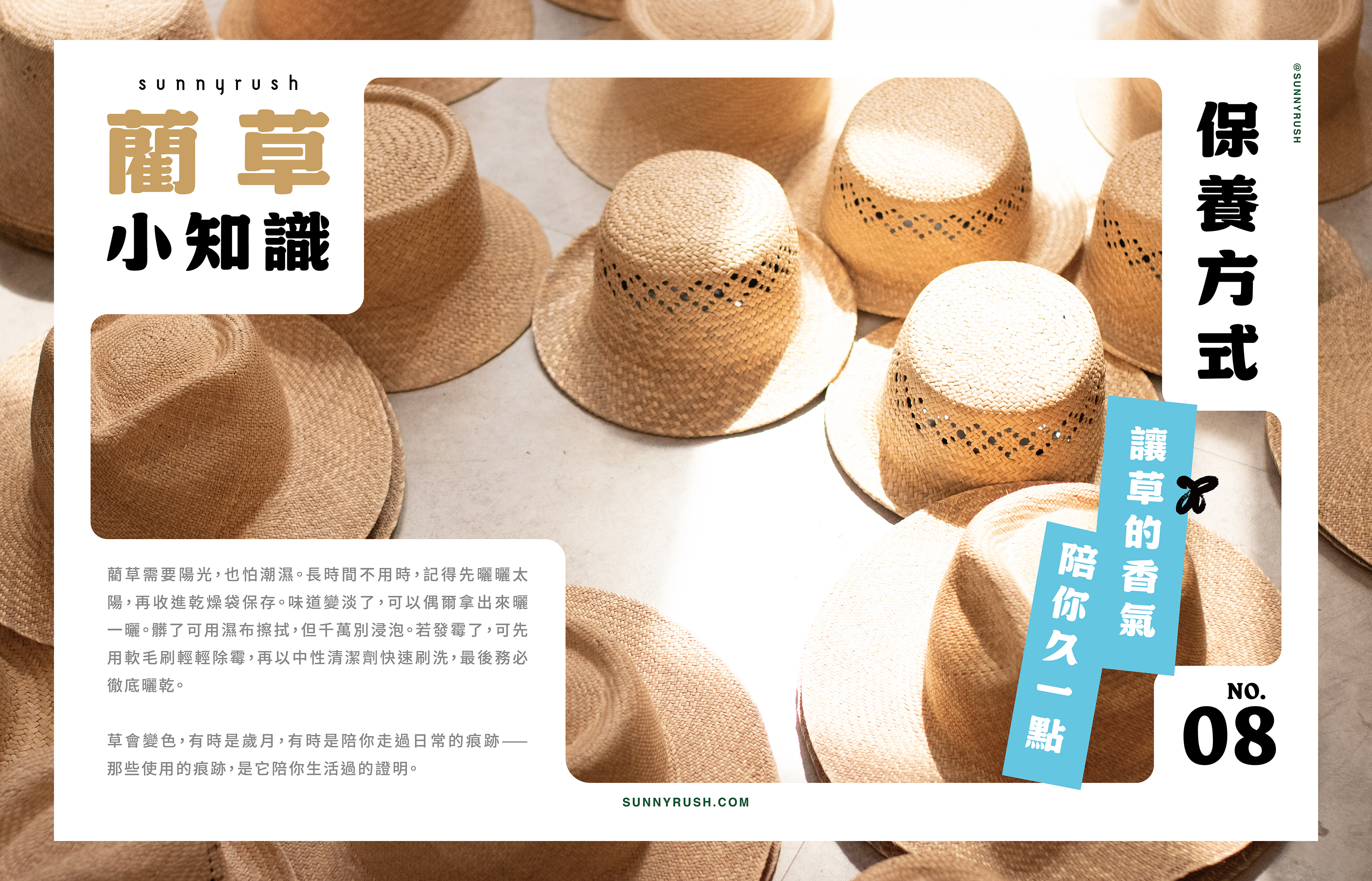

Rush Fact 08: Care Tips

Keep the Scent of Rush with You Longer

Rush loves sunlight but dislikes humidity. When not in use for long periods, let it sunbathe before storing it in a dry bag. If the scent fades, occasional sun exposure can help refresh it.

For cleaning, wipe gently with a damp cloth — never soak it. If mold appears, brush it off gently with a soft brush, clean quickly with mild detergent, and make sure to dry thoroughly under the sun.

Rush may change color over time — sometimes from age, sometimes from the marks of daily life. These traces are proof of the time it has spent with you.

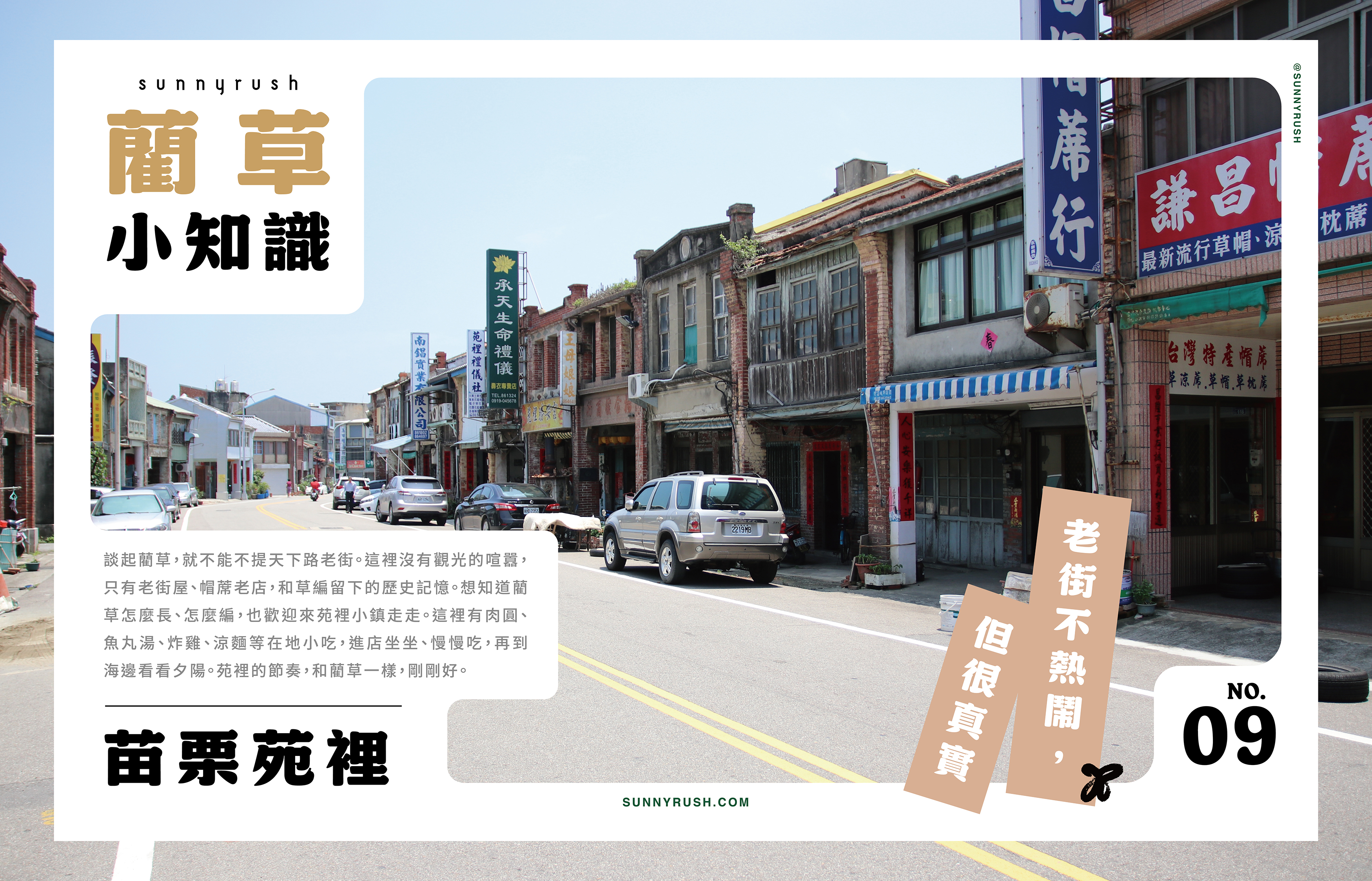

Rush Fact 09: Yuanli, Miaoli

The Old Street Is Quiet, but Real

When talking about rush, you must visit Tianxia Road Old Street. There’s no tourist hustle here — only old houses, rush shops, and memories left by the craft.

If you want to see how rush grows and how it’s woven, come and stroll through Yuanli. Enjoy local snacks like meatball dumplings, fish ball soup, fried chicken, and cold noodles. Sit, eat slowly, then head to the beach to watch the sunset.

The pace of Yuanli — like rush — is just right.

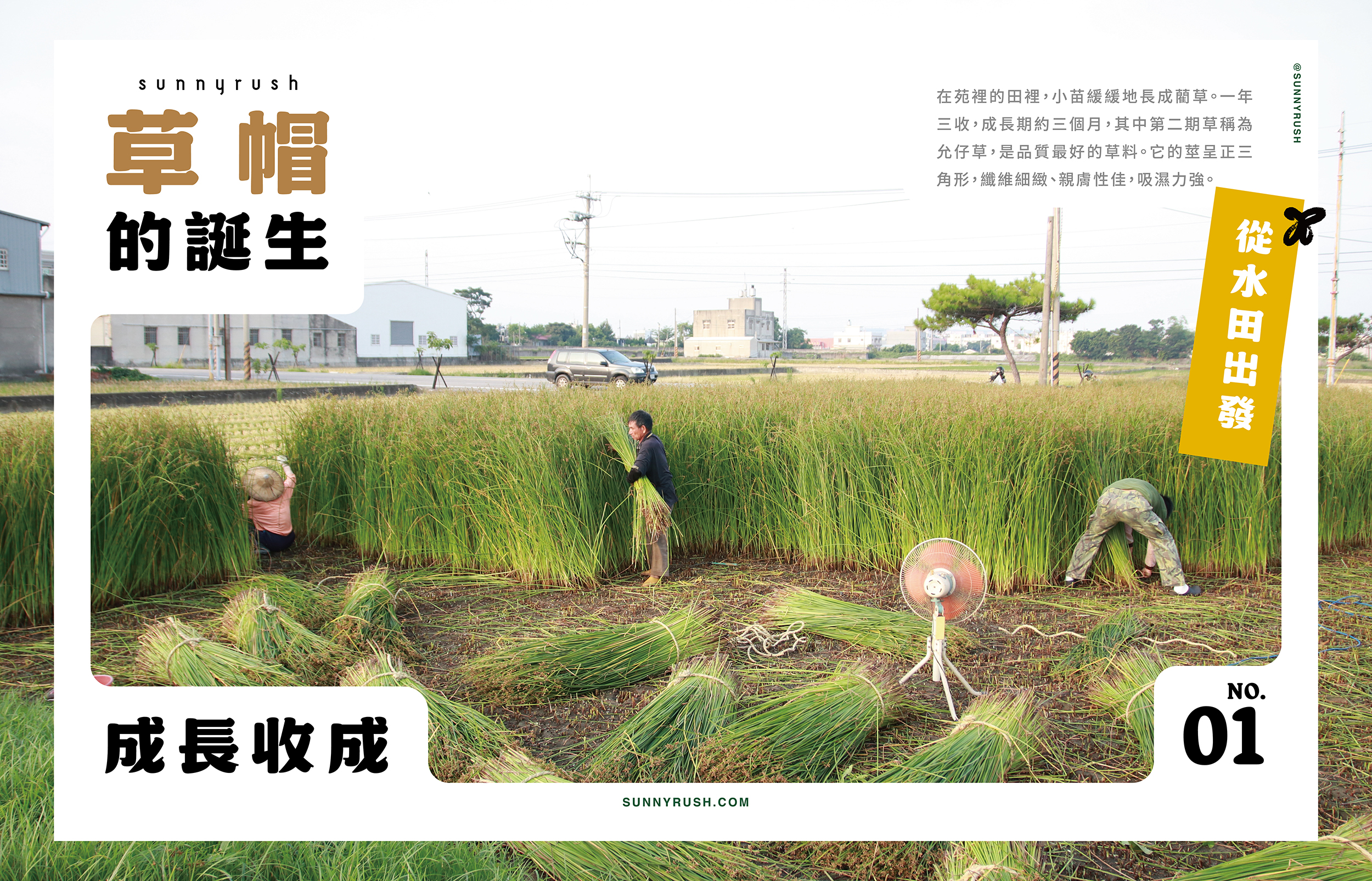

The Making of a Rush Hat 01: Growth & Harvest

It All Begins in the Fields

In Yuanli’s paddy fields, young seedlings slowly grow into rush. Harvested three times a year, each growth cycle takes about three months. The second harvest, called "Yun-Zai Grass," produces the finest quality rush.

Its stems are perfectly triangular, with delicate fibers that are soft to the touch, skin-friendly, and highly moisture-absorbent.

The Making of a Rush Hat 02: Sun-Drying

Bringing Out the Scent of Sunshine

After harvesting, rush is laid out in open spaces to soak up the sun, drawing out its natural fragrance. With each drying session, the grass turns a richer golden color.

Sun-dried rush takes on a natural sheen and a light scent that repels insects and eliminates odors — a gift from nature.

The Making of a Rush Hat 03: Grading the Rush

Grandma’s Lesson in Selecting Grass

“I only want Yun-Zai Grass!”

Every grandma has her own preferences. By judging the color and thickness of each stalk, they select the materials that best match their unique weaving styles.

The Making of a Rush Hat 04: Preparing the Rush

No Shortcuts Allowed

Preparing rush is true craftsmanship before weaving begins: stripping, splitting, pounding, rubbing, and flattening.

Only by carefully completing each step can the weaving process flow smoothly and create fine, delicate patterns.

The Making of a Rush Hat 05: Weaving

The Soul of the Rush Hat

With skillful eyes and steady hands, grandmas weave the prepared rush, tightly overlapping each stalk to create firm, delicate patterns.

On average, it takes about 40 hours to weave a single fine-weave gentleman’s hat.

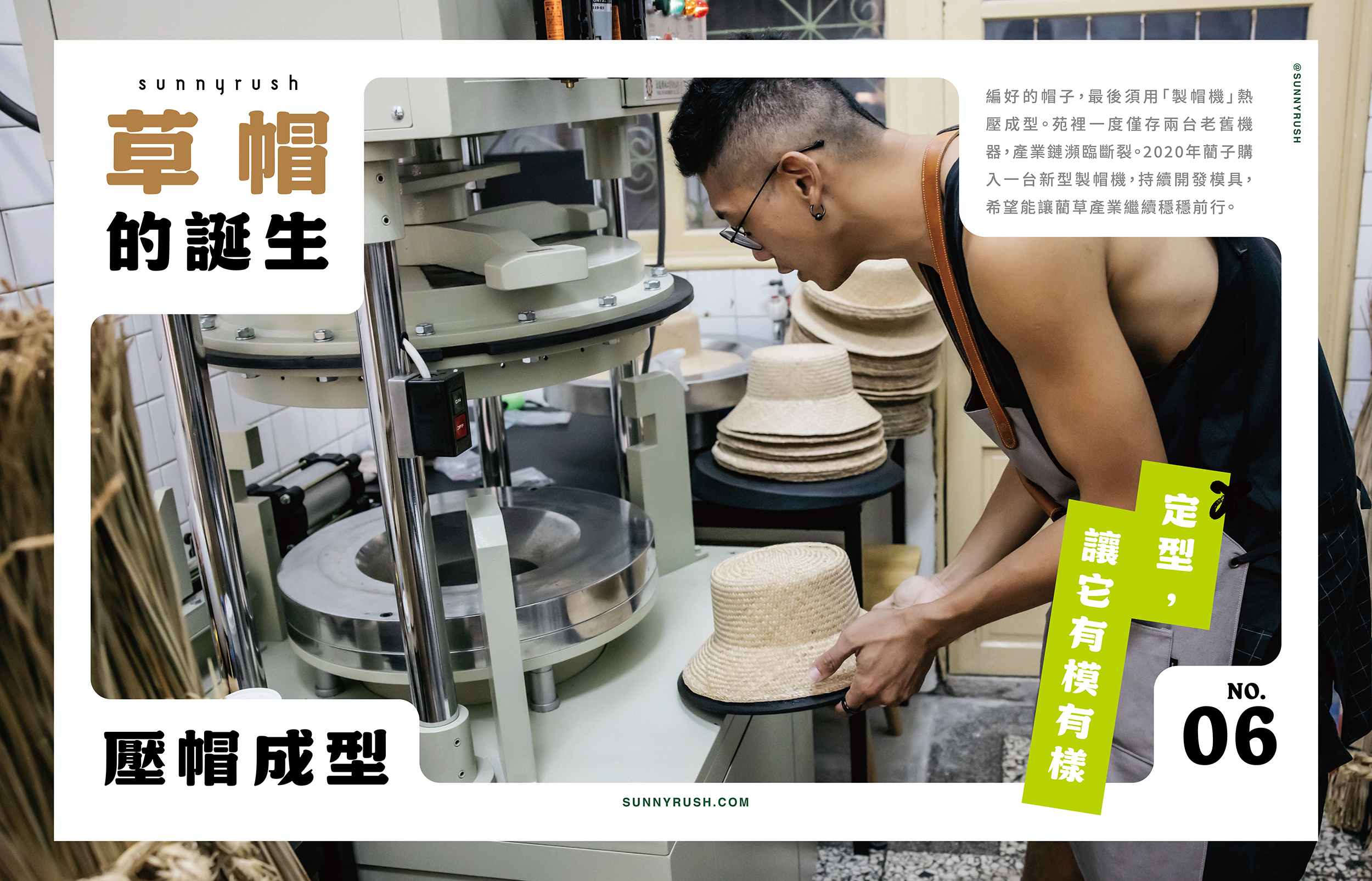

The Making of a Rush Hat 06: Shaping the Hat

Giving It Form

Once woven, the hat is heat-pressed into shape using a molding machine.

At one point, only two aging machines remained in Yuanli, putting the entire industry at risk. In 2020, Sunnyrush acquired a new molding machine and continues developing molds to help keep the rush hat craft moving forward.

The Making of a Rush Hat 07: Sewing the Hatband

The Final Touch Before Its Debut

After shaping, the hat receives its finishing details — a sweatband is stitched inside, and the hatband is sewn on.

At last, a fully handwoven rush hat is complete!